How to Identify and Replace a Bad Idler Pulley

The engine is the power source in a car. It produces all the energy which is used to turn the wheels. Apart from movement, the engine is also responsible for powering other components which enable you have a safer and more comfortable drive. Components such as the air conditioning compressor, water pump, alternator and power steering pump are also powered by the engine.

Energy produced by the engine comes as a result of linear motion (up and down movements of pistons) but it has to be converted into rotary motion. It is drive belts like the one on an idler pulley which transmit rotary motion from the engine crankshaft into power which can be utilized by these components. Most vehicles have only one idler pulley. Some specialized vehicles have more than one.

In a Hurry? Our Top Choices of “THE” Most Popular Idler Pulleys

How Does An Idler Pulley Work?

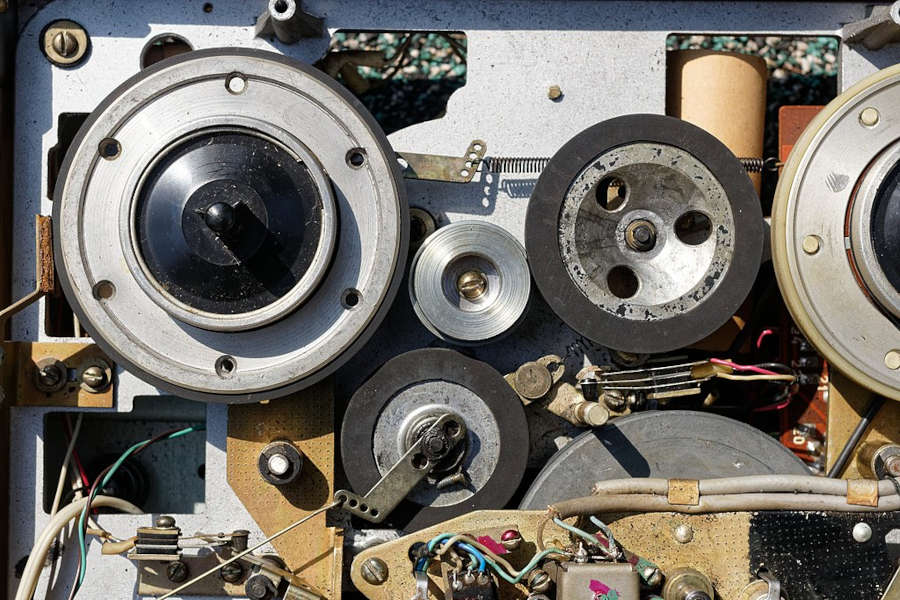

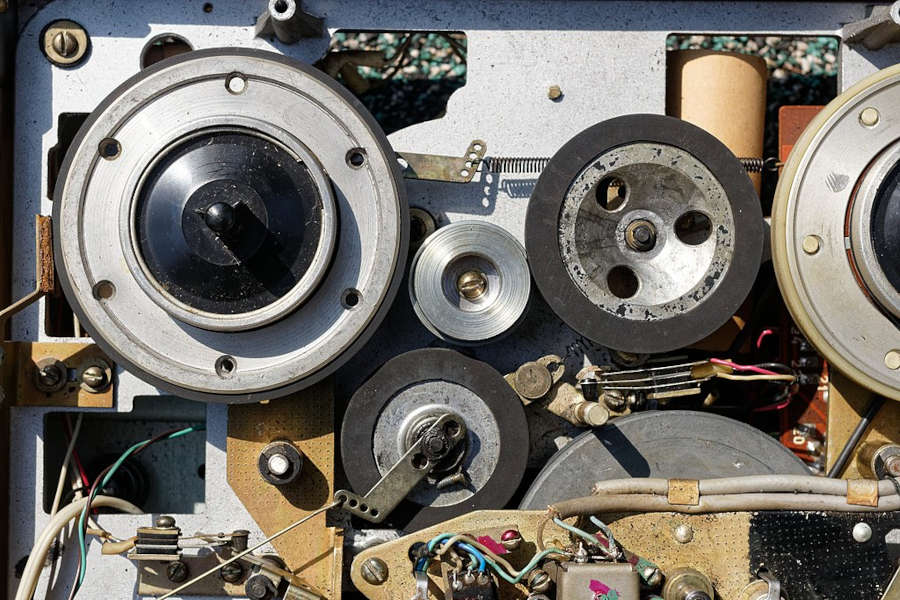

The idler pulley is one of a set of pulleys which drive the belt system in a vehicle. It provides a smoothly rotating point, preventing slack therefore allowing the engine belt drive to move and loop around.

It has a component called a sheave or wheel which has a groove which runs along its end. The belt sits in the groove and runs over the roller. When power is produced by the crankshaft, it rotates the wheel enabling speed, torque and transmission of mechanical power. The groves ensure the belt doesn’t slip out of position.

Symptoms of a Faulty Idler Pulley

These pulleys are made of either metal or plastic, so it is not a surprise that they do wear after continued use. These are some typical signs you may notice when the idler pulley is faulty.

Squealing

It is probably a good thing that this is not a symptom you can easily ignore. You turn on the engine and start to drive off but that high-pitched squealing noise coming from under the hood is enough to make you change your plans for the morning and head straight to the repair shop.

Squealing is generally caused by too much, unwanted friction on a surface where things should be moving smoothly.It is heard when the surface of the pulley is worn and is no longer smooth. Movement of the belt is still continuing so it repeatedly rubs on the surface.

This noise could also be as a result of idler pulley bearings gone bad. Bearings allow the pulley to rotate smoothly on its base. If this is the case, other noises like rumbling and cluttering may also be heard.

Visible wear

When a pulley has been used over time, more so when it starts to produce squealing noises, there are always visible signs of wear on the surface of the pulley.

That said, you would only be able to identify this symptom if you usually inspect parts of your engine even when nothing is wrong. First you would have to know where the idler pulley is. Secondly, you would have to know what its surface looked like when it was new or in relatively good condition. This way you can tell when it is worn out. Generally, you are looking for scuff marks or scorching on the surface of the pulley. The same kind of visible wear is likely to be seen on the belt as well.

Frozen pulley

It is thanks to ball bearings that the idler pulley rotates smoothly on its shaft. When there is a problem with these bearings, the pulley could stop rotating altogether or continue rotating but with rough resistance in every spin. This is a frozen pulley.

To confirm if your idler pulley is frozen, you have to slip the belt off the pulley. Before you start, make sure the engine is off and the keys are not in the ignition, just to make sure no one attempts to turn on the engine. With the belt off, try to spin the pulley with your hand a few times and observe its movement. It should spin smoothly. If it doesn’t, you probably need to replace the pulley.

Belt travel

If you look at the belt when the car is running at idle, it moves quite smoothly along the system. When there is significant deterioration of pulley hardware, the belt moves from side to side. You will notice that it shakes or wobbles as it moves. The belt becomes lose and is unable to maintain required tension. When belt wobbling continues for some time, it can partially or fully push the belt off the pulley so the pulley continues rotating with nothing on it.

Sometimes the middle groove on the pulley’s surface widens. Although the belt continues to move, it is destabilized.

Damaged bracket

The idler pulley is mounted on a bracket. In some cases, the idler pulley is perfectly fine and the bearings are fully functional but the bracket on which it is mounted is warped or has come lose. These brackets can come lose due to excessive vibration which loosens the bolt which holds it in place.

The idler pulley relies on a stable mount to work properly. If this mount is unstable, the belt could travel off the pulley. Fortunately, tightening a loose bracket bolt is a quick and easy job.

Power steering problems

As mentioned, the idler pulley is responsible for transmittingpower from theengine to other components. One of them is the power steering pump. It then follows that when there is a problem with the pulley and belt, you may have challenges when steering your car. Steering may become more difficult and in some cases it may be impossible to move the steering wheel from side to side.

What Happens If The Serpentine Belt Breaks?

Serpentine belts, also known as fan belts, alternator belts or accessory drive belts can break. When this happens, you will notice faults related to the primary functions of the belt.

The belt provides power to the power steering pump, air conditioning system and cooling system. In some cars it also powers water pumps, radiator fans and power brakes.

For starters you will notice a sudden loss of power steering which makes the wheel very hard to turn. You may find that the engine starts to overheat because the cooling system is now disabled. Electric components like lights, the radio and power windows may fail because the alternator which recharges the battery is also disabled. Generally, if the belt breaks, the car will stop running.

Common Belt or Tensioner Problems Which Could Make a Belt Break

Regular wear and tear: Wear and tear is inevitable. Your serpentine belt will need to be replaced at some point. Exactly how long you have depends on what material it is made from and how old your car is.

Oil leaks:If an engine develops an oil or coolant leak around the belt area, it gets onto the belt. Oil can damage a belt quite fast. A continuous oil leak can cause a serpentine belt to be completely damaged in as little as a week. In this case, the first remedy is to fix the oil leak.

Bad spring-loaded automatic belt tensioner: Tension is essential to proper working of the serpentine belt. A tensioner is used to maintain tension and when it seizes up or wears, tension is lost. The belt may start slipping off the pulley or slip off completely. In both cases it causes the belt to wear out faster.

To solve this problem, replace the serpentine belt and the tensioner. A spring-loaded automatic tensioner costs between $20 and $50. Labor should cost you between $75 and $150.

Misaligned belt pulley:If for some reason the serpentine belt is not perfectly aligned with the pulley, the characteristic squeaking sound will be heard when you drive. It also makes the belt get worn out faster. If you are familiar with basic working of the engine, you will be able to notice that something is out of place when this happens.

Noisy idler pulley or tensioner bearing:The idler pulley spins on a small but crucial bearing. If it wears out or is faulty, it produces a whining or screeching noise. Several of the belt-driven components can have this problem and produce the same sound. A technician would need a mechanic’s stethoscope to locate the exact source of the noise.

Manual belt tension not adjusted:In some cars, serpentine belt tension adjustment is done manually. After continued use, the belt stretches and loses some tension. If it is not readjusted manually, it starts to slip off the pulley.

The solution to this problem is not complicated. If the belt has slipped out of position but is still in good condition, simply readjust it manually. If it is baldy worn out, replace it and adjust the tension on the new belt appropriately.

How to Prevent Idler Pulley from Going Bad

The best way to make sure you never get caught flat- footed with a broken serpentine belt is to check it regularly. Make a point to check the integrity of the belt as well as pulleys at least once a month. This way you will notice wearing as it happens and plan to replace it long before it breaks.

After How Many Miles Should A Serpentine Belt Be Replaced?

Older generation vehicles had belts which lasted about 50,000 miles. Nowadays, with advancements in technology, stronger rubber belts should take you between 60,000 and 100,000 miles.

Replacement cost: Like happens with many replacement jobs, labor cost accounts for a larger part of the overall cost than the faulty part. It will cost you between $90 and $200 to replace a belt. A new belt costs between $25 and $75 while a qualified technician’s time costs between $75 and $120.

Conclusion

Idler pulleys are part of a somewhat complex belt system in your car’s engine. Many years ago, car manufacturers used separate belts to run individual components. The advantage of this was that each belt could be replaced individually but the downside was inconsistent performance.

Today, manufacturers use a single serpentine belt which runs along all pulleys which keep all your car’scomponents running. A squealing noise coming from the engine is the most distinct symptom of a faulty idler pulley though freezing, belt travel and power steering issues are also clear signs of pulley problems.

The best way to make sure your idler pulley and serpentine belt never leave you stranded on the side of a road is to check the system regularly. Make sure you are familiar with the system, its components and how they all look when in proper working condition. This way you will easily identify a problem when it arises.

FAQs

Can you drive without an idler pulley?

The idler pulley is part of the entire belt system which powers essential components. It would be next to impossible to drive without an idler pulley. It would be very difficult to steer the car because thepower steering system depends on this pulley. The alternator also depends on this belt so without it the alternator and the battery would not work so you may not be able to start the car.

Does the idler pulley cause rough idling?

A faulty idler pulley can be the reason behind rough idling. The pulley and serpentine belt are responsible for transmitting power to certain components including the alternator. If the idler pulley is not functioning properly, the alternator doesn’t recharge the battery enough so it doesn’t have enough energy to run the ignition.

How long will a cracked serpentine belt last?

There is no clear cut answer as to how long you have with cracks on your serpentine belt. Small cracks across the ribs of a belt are quite common, even on a fairly new belt. They generally don’t affect performance if they are few.

When the number of cracks increases, then you have something to worry about. The general rule is that if there are 3 or more cracks in a 3-inch length of belt, then you have no more than 20% of its life left.

The average lifespan of a serpentine belt is between 60,000 and 100,000 miles. Taking this to be 100% of its life, you can do the math. 3 or more cracks in a 3 inch length means you have between 12,000 and 20,000 miles of use left.

How is idler pulley replacement done?

If you have some basic knowledge of how the pulley fits into the system, you can replace it yourself. If not, take your car to a mechanic. It takes about half an hour to replace. Here is the summarized procedure.

- Disconnect the battery. Disconnect the negative cable from the battery. This ensures there is no current running through.

- Remove the belt.

- Remove the old pulley. You will need to remove the bolt which holds it in place then pull the pulley out.

- Install the new pulley. Compare the old one and the new one to make sure the new one is a right fit.

- Torque the pulley. Use a torque wrench to torque the pulley to 40ft/lb.

- Replace the belt. This part can be confusing if you don’t have much practice. Be careful to follow the belt path correctly.

- Reconnect the battery.