Essential Information Every Car Owner Needs About Idler Pulleys

Replacing a failing idler pulley before it destroys your serpentine belt can save you from costly engine damage and roadside breakdowns. Understanding these warning signs keeps your vehicle running smoothly.

The engine serves as your vehicle’s powerhouse, generating energy that turns the wheels and powers essential components like air conditioning, water pump, alternator, and power steering pump. This energy transfer relies on drive belts working with idler pulleys to transmit rotary motion from the engine crankshaft to these critical systems.

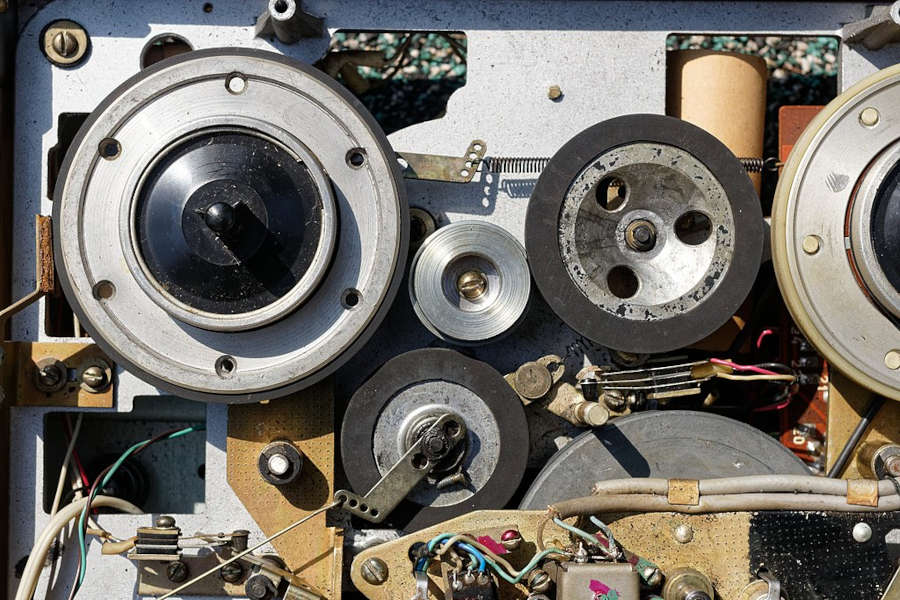

Understanding how idler pulleys function reveals why they’re essential for your vehicle’s operation. The idler pulley is one of a set of pulleys which drive the belt system in a vehicle. It provides a smoothly rotating point, preventing slack therefore allowing the engine belt drive to move and loop around.

It has a component called a sheave or wheel which has a groove which runs along its end. The belt sits in the groove and runs over the roller. When power is produced by the crankshaft, it rotates the wheel enabling speed, torque and transmission of mechanical power. The groves ensure the belt doesn’t slip out of position.

Critical Warning Signs of Idler Pulley Failure

Squealing Noises represent the most recognizable symptom of pulley problems. You turn on the engine and start to drive off but that high-pitched squealing noise coming from under the hood is enough to make you change your plans for the morning and head straight to the repair shop.

This noise occurs when friction increases beyond normal levels. The pulley surface becomes worn and loses its smooth texture, causing the belt to rub repeatedly against damaged areas. Failed bearings within the pulley create additional sounds including rumbling and chattering.

Visible Surface Damage appears on pulleys after extended use, particularly when squealing begins. Look for scuff marks or scorching on the pulley surface – these indicate excessive friction and heat buildup. Similar wear patterns typically appear on the serpentine belt itself.

Frozen Pulley Operation happens when internal ball bearings fail completely. The pulley either stops rotating entirely or moves with significant resistance during each revolution. Testing requires removing the belt and manually spinning the pulley – it should rotate smoothly without binding.

Belt Movement Issues become apparent during engine operation at idle. When pulley hardware deteriorates significantly, the belt moves side-to-side instead of tracking straight. This wobbling motion can eventually push the belt completely off the pulley, leaving it spinning without purpose.

Damaged Mounting Brackets sometimes cause pulley problems even when the pulley itself functions properly. Excessive vibration loosens mounting bolts, creating an unstable foundation. Fortunately, tightening loose bracket bolts represents a quick, straightforward repair.

Power Steering Difficulties develop when the idler pulley fails to transfer adequate power to the steering pump. Steering may become more difficult and in some cases it may be impossible to move the steering wheel from side to side.

Understanding these serpentine belt maintenance fundamentals helps prevent unexpected failures. For comprehensive information about serpentine belt replacement procedures, reference additional resources.

Consequences of Serpentine Belt Failure

When serpentine belts break completely, multiple vehicle systems fail simultaneously. You’ll immediately lose power steering, making the wheel extremely difficult to turn. The cooling system becomes disabled, potentially causing engine overheating. Electrical components like lights, radio, and power windows may fail because the alternator stops recharging the battery.

Common causes of belt failure include:

Regular Wear and Tear: All belts eventually require replacement based on material composition and vehicle age.

Oil and Coolant Contamination: Engine leaks around the belt area cause rapid deterioration. Oil damage can completely destroy a serpentine belt within one week of continuous exposure.

Faulty Automatic Tensioners: When spring-loaded tensioners seize or wear out, proper belt tension disappears. This causes slipping and accelerated wear patterns.

Pulley Misalignment: Incorrectly aligned pulleys create characteristic squeaking sounds and premature belt wear.

Bearing Failures: The idler pulley spins on small but crucial bearings. When these wear out, whining or screeching noises develop.

Manual Tension Problems: Some vehicles require manual belt tension adjustment. Stretched belts lose tension over time without proper readjustment.

Modern serpentine belts typically last 60,000 to 100,000 miles compared to 50,000 miles for older generation belts. Replacement costs range from $90 to $200, with parts costing $25-$75 and labor charges between $75-$120.

For detailed information about vacuum line maintenance, which affects overall engine performance, consult specialized resources.

Prevention and Maintenance Strategies

Monthly visual inspections represent the most effective prevention method. Check belt integrity and pulley condition regularly to identify wear patterns before complete failure occurs. This proactive approach allows planned replacement rather than emergency repairs.

Learn to recognize your belt system components and their appearance when functioning properly. This knowledge enables quick problem identification when issues develop.

Professional Replacement Process

Idler pulley replacement typically takes approximately 30 minutes when performed correctly:

- Disconnect the battery negative cable to eliminate electrical current

- Remove the serpentine belt following proper routing procedures

- Extract the old pulley by removing the mounting bolt

- Install the new pulley ensuring proper fit and alignment

- Torque the pulley to 40 ft/lbs using appropriate tools

- Replace the belt following the original routing pattern

- Reconnect the battery and test system operation

Driving without an idler pulley becomes virtually impossible due to power steering system dependence and alternator requirements for battery charging and ignition operation.

Rough idling can result from faulty idler pulleys when alternator function becomes compromised, reducing battery energy available for ignition systems.

Cracked serpentine belts provide limited remaining service life. The general rule is that if there are 3 or more cracks in a 3-inch length of belt, then you have no more than 20% of its life left. With average belt lifespans of 60,000-100,000 miles, this translates to 12,000-20,000 miles remaining.

Recommended High-Quality Replacement Products

Based on extensive market research and customer feedback, these products offer superior reliability and value:

Gates Complete Serpentine Kit (Model 90K-38178A)

This comprehensive replacement system includes the serpentine belt, three pulleys, and tensioner assembly. Gates products deliver 98% power efficiency with temperature-stable construction from -22°F to 176°F. The polychloroprene rubber construction with polyester fiber tensile members provides exceptional durability. Over 1,400 verified purchases with consistently positive reviews make this an excellent choice for complete system replacement.

06/11/2025 10:57 pm

ACDelco Professional Idler Pulley Assembly

ACDelco’s aftermarket pulleys meet OEM specifications while offering improved bearing technology. These pulleys feature premium sealed bearings designed for extended service life under demanding conditions. Multiple vehicle applications make ACDelco a versatile choice for various makes and models. Professional technicians frequently recommend ACDelco for its reliability and competitive pricing.

06/11/2025 10:57 pm

Dayco Drive Belt Idler Pulley (Model 89372)

Dayco’s engineering focuses on reducing wear, friction, and vibration throughout the drive system. With over 285 customer reviews averaging 4.4 stars, this pulley demonstrates proven reliability. Dayco’s heavy-duty construction extends belt service life while maintaining proper tension and alignment. The company’s OEM supplier status for multiple manufacturers ensures quality standards.

06/11/2025 10:57 pm

Continental OE Technology Series Belt (Model 4060860)

Continental’s 6-rib, 86.0″ multi-V belt represents advanced belt technology with enhanced durability. This belt receives high ratings from over 75 verified customers who appreciate its quiet operation and extended service life. Continental’s OE technology ensures compatibility with modern engine demands while providing superior power transmission efficiency.

06/11/2025 10:57 pm

Motorcraft Tensioner Pulley (Model YS-335)

Ford’s OEM supplier provides tensioner pulleys engineered specifically for optimal performance. With 93 customer reviews averaging 4.7 stars, Motorcraft demonstrates exceptional quality and reliability. Professional mechanics often prefer OEM components for critical applications where failure could cause significant damage.

06/11/2025 10:57 pm

For Honda-specific maintenance procedures, including radio code retrieval, consult manufacturer-specific guides.

Understanding Modern Belt Systems

Contemporary vehicles typically use single serpentine belts instead of multiple V-belts found in older designs. This advancement improves efficiency and simplifies maintenance while reducing space requirements in the engine compartment.

Single belt systems offer several advantages:

- Higher tension capability without stretching

- Reduced slip for increased belt life and mechanical efficiency

- Lower-ratio pulleys reduce engine load

- Improved fuel economy and available power

- Easier maintenance and replacement procedures

- Elimination of belt “flip-over” problems at high RPM

However, single belt dependency means complete system failure when one component breaks. This makes regular inspection and proactive replacement even more critical for modern vehicles.

Regular maintenance and prompt attention to warning signs ensure reliable vehicle operation while preventing costly emergency repairs. Understanding idler pulley function and failure symptoms empowers car owners to make informed maintenance decisions.

Related Posts

- The Complete British Driver’s Guide to Choosing the Best Car Air Filter

- VW T5 1.9 TDI — The Sweet Spot of Reliability and Performance

- Why Does The Check Engine Light Stay On After Fixing Problem: Complete Troubleshooting Guide

- Engine Noises That Demand Your Immediate Attention

- Top 5 Fuel Filter Brands: The Ultimate Comparison Guide